Home > RFID News > RFID Technical

Tracking Tools With OPPD5 UHF RFID Tag

2018-2-2 View:

Thousands of tools worth thousands of dollars are stored on the shelves of hospitals, manufacturing plants, and construction yards, yet many of these tools lack any organization, security, or tracking methods. RFID can be a considerable, upfront investment, but it can help protect a company’s assets. Where some people see a box full of tools, others see a box full of company money with no security measures present.

Tracking tools with RFID requires adhering RFID tags to each utensil in order to maintain and manage hundreds or thousands of tools and minimize loss and replacement. When each tool is tagged, and hardware and software components are setup correctly, the user can have visibility into inventory rooms, tool cribs, and even mobile tool boxes. Construction, healthcare, manufacturing, or any industry or company with thousands of tools on hand could benefit from RFID tool tracking.

In order to successfully track these tools, both hardware and software are required. Tags, readers, antennas, cables, and software together create RFID tool tracking systems for use in warehouses, construction yards, sterilization rooms, and trucks. Five common RFID tool tracking systems are mobile inventory systems, tool picking systems, inventory control systems, check in/check out systems, and tool history systems. For a deeper look into the problems that these solve, read Manage Preventative Tool Maintenance with RFID.

Choosing an

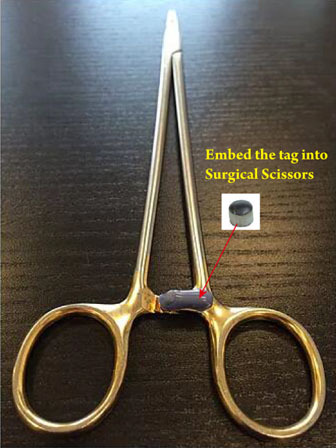

UHF RFID tag that will yield the best read range is a complex decision, as it is necessary to understand the limitations and restrictions of the tracked tools. Many tags work well for tool tracking applications, but they can be narrowed down depending on the shape and size of the tool. It is also important to understand how these tools will be tagged, whether that means epoxy, embedding, or screws and rivets. For RFID tag options, as well as hardware options, download our Tool Tracking Buyer’s Guide for a better understanding of where to start.

The required RFID hardware differs greatly depending on what type of tool tracking system is being set up on location. Excluding tool picking systems, most RFID tool tracking systems will require a fixed reader and antennas, but whether those pieces are in a portal depends on the environment and specific system. Handheld readers are very useful in all tool tracking systems as the handhelds help identify specifics tools and read/write RFID tags.

OPP IOT Technologies Co., LTD., concentrate on the design, develop,manufacture of the UHF special tags.Our UHF tags

OPPD5 work well in tool tracking,It is only 4.0mm thickness,diameter 5.0mm,weight 0.5g,FR4 board ,Alien Higgs-3 chip,good performance attached directly on metal surface. It is a full solutions for efficient management of surgical and other hospital equipment.

OPPD5 UHF tags not only application in tool tracking, but also application in Instrument tracking, Medical device management, Source tagging, Surgical instrument management, Small asset tracking, IT and laptop tracking, embedded bolt identification and Weapons tracking.

![]()